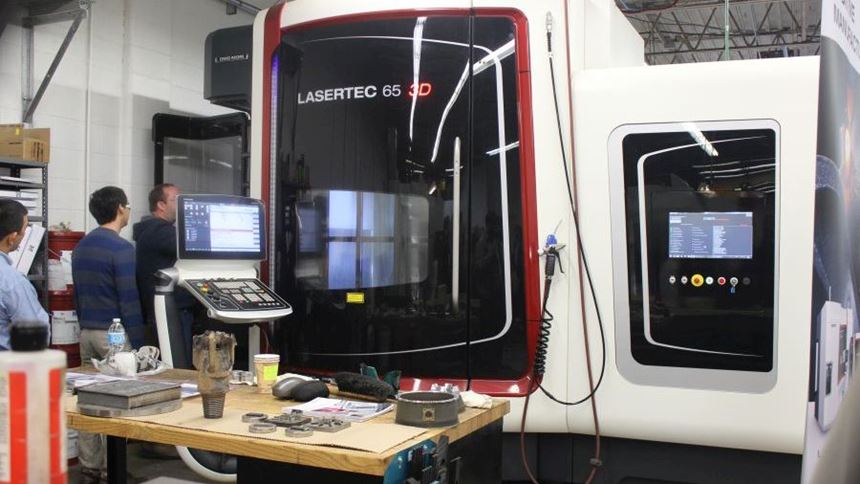

LASERTEC 65 3D hybrid - Machines for additive manufacturing using a powder nozzle and generative manufacturing with the powder bed process from DMG MORI. LASERTEC 65 3D hybrid - Machines for ADDITIVE MANUFACTURING by powder nozzle and in powder bed by DMG MORI.

Flexibility by the combination of additive and turning machining process for 3D-parts in finished quality

- Large parts up to Ø 660 mm, 660 mm in Z (axial) or up to Ø 545 mm, 1,500 mm in Z (radial)

- 5-axis material deposition by coaxial nozzle for homogeneous powder distribution, independent from direction of laser deposition welding

- Additive Manufacturing of metals and reactive materials such as Ti-6Al-4V (optional)

Process monitoring and adaptive process-control (Closed Loop)

- User friendly and specifically developed software with operator-orientated user interface and CELOS integration

- Process monitoring for highest process safety and quality management

- Continuous measuring and monitoring of the laser buildup process as well as automatic regulation of the laser power in real-time for homogeneous part qualities

Dmg Mori Lasertec 65 Hybrid For Sale

Siemens NX: Complete Hybrid CAD / CAM – Module for additive and subtractive programming

Dmg Mori Lasertec 30 Slm

- One software package for the complete process chain (design, additive process, substractive machining, finishing)

- Exclusive LASERTEC build-up strategies - fully integrated in the CAD / CAM software incl. 3D-simulation of machine and movements for collision prevention

- Shorter time-to-market due to completete integrated PLM software integration